Crystalline scintillators for physics, medicine, safety, engineering.

€а

A set of technological processes is developed in the Institute of Solid State Physics RAS for manufacturing of scintillation elements for radiation detectors with high space resolution. The technologies developed enable to enhance the sensitivity of scintillation detectors and improve their space resolution as well as decrease significantly the production cost of scintillators.

The new technologies include:

тАв€а an economic method of synthesis of initial scintillation materials, enabling to produce a wide set of complex oxides, doped with various activators of light emission;

тАв€а a technology of direct forming of scintillation elements with necessary profiles and dimensions by means of external pressure in pressing tools with corresponding geometry. An additional advantage of this method is connected with the opportunity to fanricate optical smoothness of external surfaces immediately in the process of forming. This is achieved by arrangement of corresponding conditions of forming when roughnesses of external surfaces are flattened by means of local plastic deformation of subsurface layers of the scintillator.

The practical effectiveness of the method of plastic forming is tested in the experimental production of scintillation elements from alkali halide crystals (cesium iodide, etc.). It should be emphasized that optically smooth surfaces fabricated by compression of preliminary polished dies have several qualitatively new characteristics:

тАв€а Microroughness of the formed elements characterizing their resistance to scratching is higher significantly in comparison with those made by traditional abrasive way.

тАв€а Deformation polishing produces anti €Ц hydroscopic effect as well: the elements from alkali halide crystals can be kept at open air without noticeable damage during several years.

тАв€а Plastic forming enables manufacturing of superthin scintillation elements from cesium iodide with the thickness not more than 0.4 mm and transverse dimensions more than 100 mm, what can not be made by other methods.

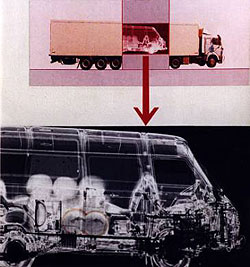

Inspection gamma €Ц transmission control of a truck container.

Several technological methods developed in ISSP are applied successfully in production of scintillators from lead tungstate for the biggest in the world accelerator of elementary particles being constructed at Geneva (this accelerator needs about 100,000 kg of these crystals).

On the basis of matrix detectors using scintillators from cadmium tungstate produced in ISSP it is developed a transmission gamma apparatus for inspection control of truck containers. The procedure of control of 15 €Ц meter container takes 2 minutes only. (Two revolver, hidden inside the microbus transported in the container are seen distinctly at the photo).